Rigid Front Axle Suspension System:

Purpose of vehicle Suspension System:

Vehicle components and axles operate under severe stresses. Hence, they should be properly suspended to protect them from fracture or breakdown. Moreover, if the front and rear wheels running on bearings are rigidly attached to the frame, it will result in an extremely bumpy/painful ride. To avoid the transmission of road shocks to the passengers/occupants, the vehicle must insulate its wheels and axles from the chassis frame thru’ a flexible connection. For this purpose, manufacturers use different types of front suspension systems. Ideally, a good front suspension system should possess springiness and damping qualities. Rigid Front Axle Suspension is the most commonly used design for earlier generation vehicles.

Objectives of vehicle Suspension System:

Following are the objectives of the vehicle suspension system.

The front suspension system –

- Protects the passengers from road shocks. Thus, provides a comfortable ride for them.

- Prevents the vehicle body from tipping while traveling over rough ground or when turning. This helps to minimize the tendency of rolling, pitching, or vertical movement.

- Provides cushioning effect. Thus, minimizes the effects of stress on vehicle components and mechanisms.

- Maintains the vehicle body at perfect level while traveling over rough, uneven ground. This enables the up and down movement of the wheels relative to the body.

- Insulates the vehicle structure from shocks and vibrations due to irregularities of the road surface without affecting its stability.

- Provides required height to the body structure as well as bears the torque and braking reactions.

Principles of Rigid Front Axle Suspension System:

There are three fundamental principles of the front suspension system for the satisfactory springing of the motor vehicles.

They are:

- Reduction of unsprung weight i.e. the weight of the wheels and other components receiving the road shocks.

- Reduction of rolling or pitching of the body to a minimum with appropriate design and attachment of springs.

- To absorb satisfactorily small as well as large road impacts with the help of the single springing device.

Rigid Front Suspension System Design:

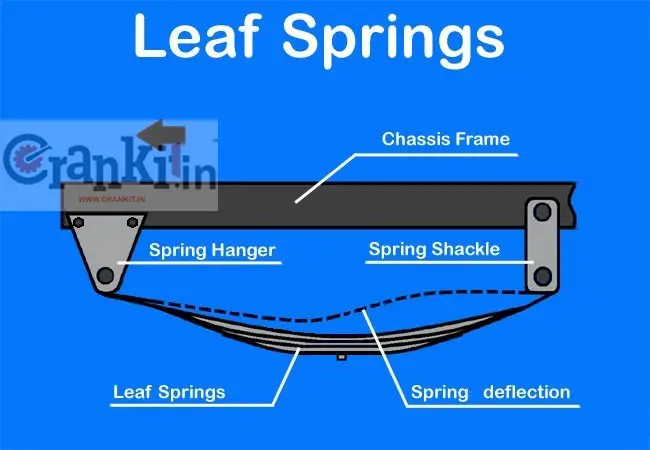

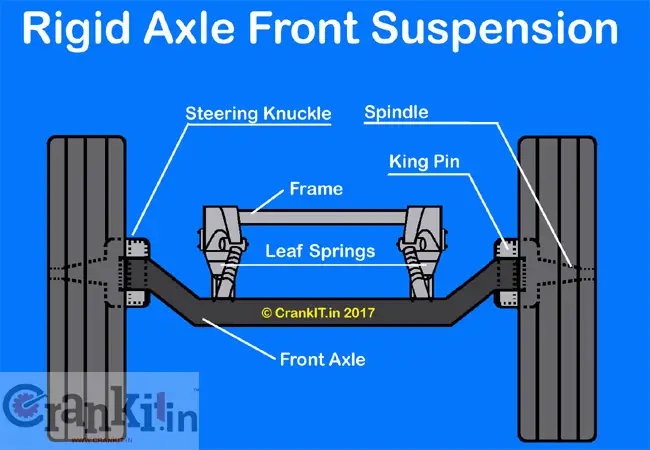

Earlier generation vehicles used the rigid front axle suspension due to its simple design. This design uses two longitudinal leaf springs or a transverse spring. The spring assembly consists of a number of curved metal strips, stacked on each other and clamped together. The spring assembly attaches to the front axle by ‘U’ bolts.

Each end of the spring connects the frame thru’ pivoted bushes by means of ‘eye-holes’ formed at the end of the longest leaf. One end of the longest leaf is secured to the front hanger by a bolt. The other end of the leaf is secured to the rear spring shackle. Both the hanger and shackle attach to the frame by a bolt as seen in the diagram.

Advantages:

The beam type rigid axle suspension is the simplest design of the first-generation suspension system. This design interconnects the front-wheels thru’ a forged rigid axle which is usually a non-drive axle. Stub-axles pivot on to each end of the front rigid axle and support the steering mechanisms for front wheels.

Many commercial vehicles still use rigid front axle suspension as it can carry more loads. Being very strong, the rigid front axle suspension can take huge impacts. The solid/rigid axle can carry heavy loads. It is very tough and doesn’t have many components. Hence, there is little or no maintenance.

Disadvantages:

- Hard springing due to a small amount of maximum spring deflection. Thus, it restricts the vertical movement to the extent of the clearance between the axle and the engine.

- Accurate control of steering geometry is not possible.

- High unsprung weight resulting in minimum wheel bonding.

- For providing clearance, the engine needs to sit behind the axle. This reduces the passenger compartment area.

- It produces an over-steer effect due to poor rolling stiffness.

Due to a number of disadvantages of the beam or rigid axle front suspension, the manufacturers use an improvised form i.e. independent front suspension for passenger cars such as sedans, coupes, and hatchbacks.

Watch Rigid Axle Front Suspension in action here:

For more information, please click here.

Read More: What is Kerb-Weight of the vehicle?>>