Independent Front Suspension System:

Purpose of Suspension System:

Due to a number of disadvantages of the beam or rigid axle front suspension, the manufacturers use an improvised version i.e. independent front suspension for passenger cars. However, earlier generation vehicles used rigid axle front suspension because of its simple design. It is also cheaper to manufacture and maintain.

Besides, its shock-absorbing property is poor which results in a bumpy ride and instability. Ideally, a good front suspension system should possess springiness and damping qualities.

Independent Front Suspension System:

In this system, the wheels connect to the frame in such a way that the movement of one wheel is not dependent on the other. Hence, each wheel acts as a separate suspension unit. The rise and fall of either wheel has no direct effect on the other. As a result, each wheel is able to maintain its level position regardless of the action of the other front wheel.

Today, most passenger cars use independent front suspension. It provides softer springing action, improved steering geometry and better bonding of wheels with the road. Additionally, this suspension improves the ride and handling qualities of the vehicle. Thus, it offers better ride comfort for the passengers.

Types of Independent Front Suspension System:

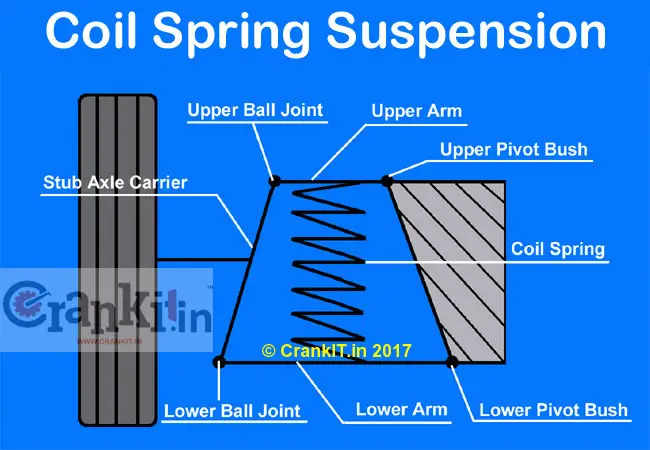

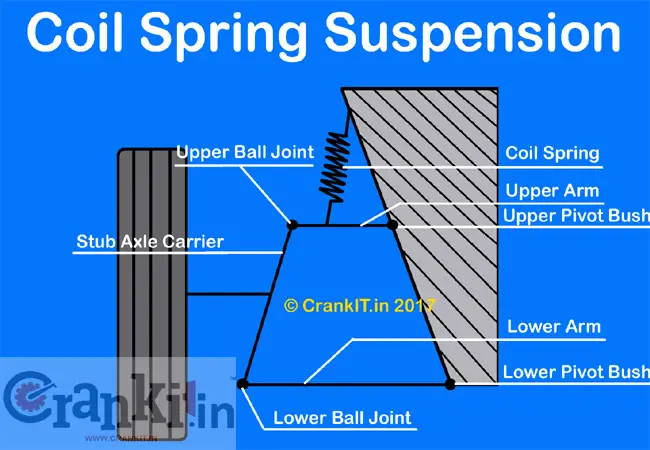

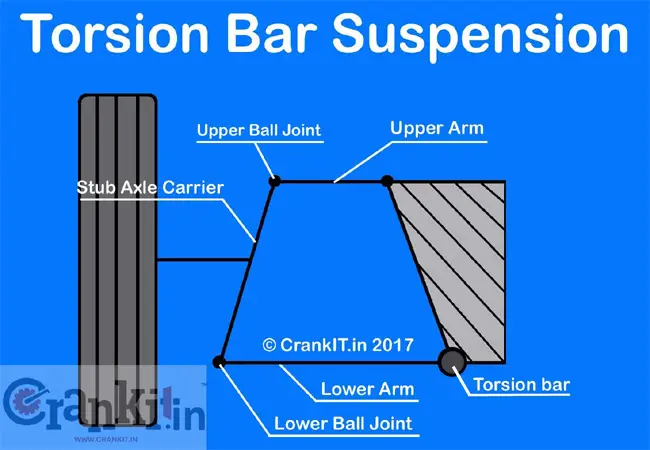

This system is also known as the parallelogram type suspension system. This is because the upper arm, lower arm, and stub axle form a shape of a parallelogram when connected. It consists of an upper arm and lower arm which attaches to the stub axle carrier or steering knuckle. Generally, the lower arm is larger than the upper arm and they may not be parallel.

1.Coil Springs type I: This design uses coil springs which provides springing action to the suspension. The spring sits between the upper and lower arms. The lower arm attaches to the frame at a single point.

2. Coil spring type II: This is the most common design which also uses coil springs. The spring sits between the upper and lower arms. However, the lower arm attaches to the frame at two points.

3. Coil Spring type III: In the third type, the coil spring sits between the upper arm and spring tower or housing which is a part of the vehicle body.

4. Torsion Bar:

This design uses a steel rod known as the torsion bar. It acts as a spring to hold the upper and lower arms parallel under load. One of its ends fits into the lower arm while the other end fits into an anchor; fixed to the frame cross-member.

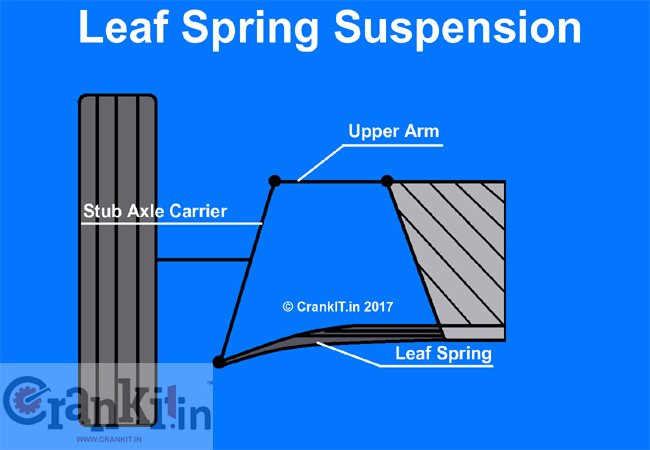

5. Leaf spring: This design uses leaf spring in place of coil spring for springing action of the suspension. One end of the leaf spring attaches to the chassis frame while the other end attaches to the lower arm.

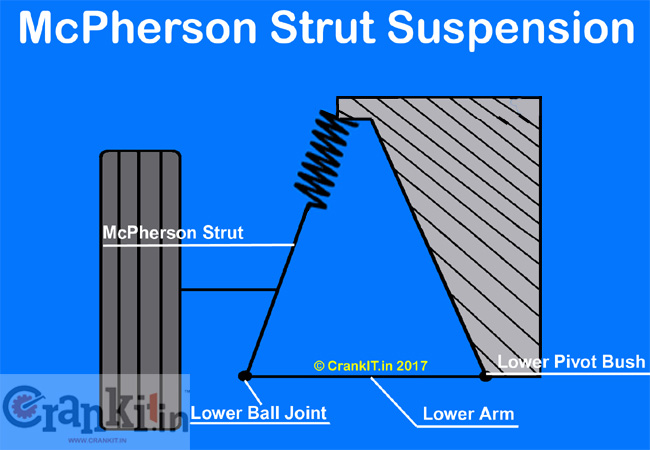

6. McPherson Strut: This design uses a special unit consisting of a spring and shock-absorber. It was named after McPherson who invented it and hence, the name. Manufacturers use this design, particularly in mono-cock body construction.

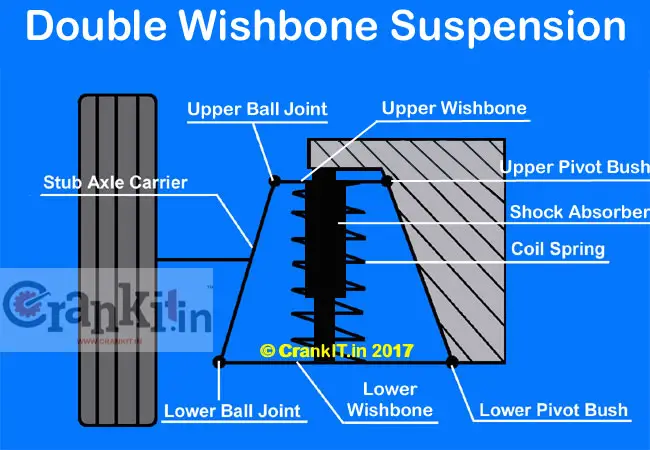

Double Wishbone Suspension:

This is an improvised version of the independent front suspension. In this design, a damper is usually installed inside the coil spring. In order to absorb shocks, manufacturers provide a spring and a hydraulic damper between each wishbone and car frame/body. The upper end of the coil spring sits in a rubber seat located in the spring bracket which is welded to the chassis frame. The lower end of the coil spring sits on a spring seat in the lower link.

One end of the lower link pivots to the chassis frame cross member through an eccentric pin and bushes while the other end attaches to the bottom of the stub axle by a ball joint. The open end of the top wishbone pivots to the frame through a spindle and bushes. The closed end of the top wishbone connects to the top of the stub axle by a ball joint. Additionally, a strut or ‘brake rod’ connected between lower wishbone and the body/chassis absorbs the braking forces. During wheel alignment, castor is adjusted by changing the length of this brake rod.

Advantages of Independent-Front Suspension:

For more information, please click here.

Watch Independent-Front Suspension in action here:

Read More: What is Rigid Axle Front Suspension?>>