What is DTS Si?

DTS Si stands for ‘Digital Twin Spark-Swirl induction’ system. Some of Bajaj’s bike engines have the patented ‘DTS Si’ (Digital Twin Spark-Swirl induction) technology. Bajaj Auto claims that new engine with swirl induction gives better mileage under ideal (standard) test conditions that are higher than some of the 100cc motorcycles offer.

Bajaj Auto’s R&D designed and developed the DTS Si technology entirely in-house. The company claims it to be India’s most fuel-efficient motorcycle engine. It claims further that this engine offers the best of both worlds. That is the average of a 100cc bike and the performance of the 125cc bike.

What is Swirl induction?

The Digital Twin Spark–Swirl induction or DTS Si technology is based on the DTS-i platform. The DTS-i provides the fast rate of combustion. Bajaj R&D found out that when burning lean air-fuel mixture, the two plugs provide rapid combustion. However, at light loads, there is further scope to improve the combustion quality.

Normally, under these conditions, the quality and concentration of the air-fuel mixture vary from one area to another within the combustion chamber. However, by generating high turbulence inside the combustion chamber; the efficiency of combustion further improves under lean air-fuel mixture conditions.

According to Bajaj R&D, the combustion chamber having low turbulence spreads the flame that is like a gradually expanding balloon. This results in a slower rate of combustion. Also, it raises the pressure slowly. So, it results in lower efficiency.

When the combustion takes place under high turbulence, the surface of the inflating flame fragments itself. It forms projections like fingers, increases the surface area. It further improves the combustion.

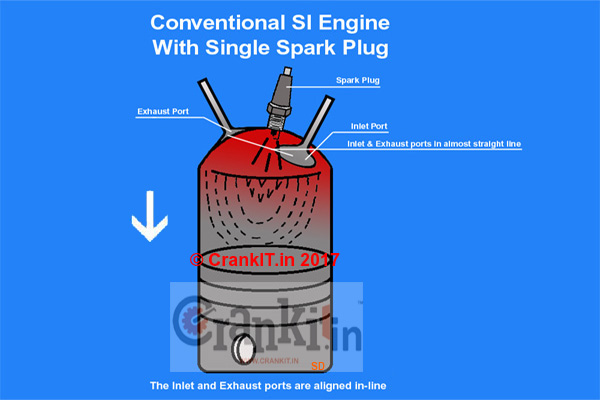

The configuration of ports:

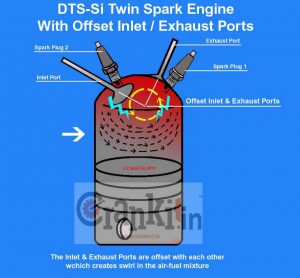

The conventional engines using straight ports have limitations in creating high swirl values due to their geometry. To create more turbulence or swirl, it needs a port configuration that stimulates this process. Bajaj engineers optimized the configuration. They did so by designing offset ports which create the required degree of the swirl. The offset positioning of the ports generates relatively high swirl and turbulence of the air-fuel mixture in the combustion chamber.

This technology finds its way into the newer engines. It creates the swirling motion of the incoming charge. Thus, it creates turbulence as the piston moves in the Intake and Compression strokes. This results in thoroughly mixing of the air-fuel mixture. And, it spreads the mixture within the combustion chamber.

The twin spark plugs provide the sparks to ignite this turbulent and compressed air-fuel mixture. This leads to a flame front of the high surface area. It quickly raises the pressure because of fast combustion. Thus, DTS-i combined with Swirl induction provides extremely fast combustion which results in better efficiency.

More information:

Read More: What is CCVTi Technology and How it works?>>