Carburettor: How it works?

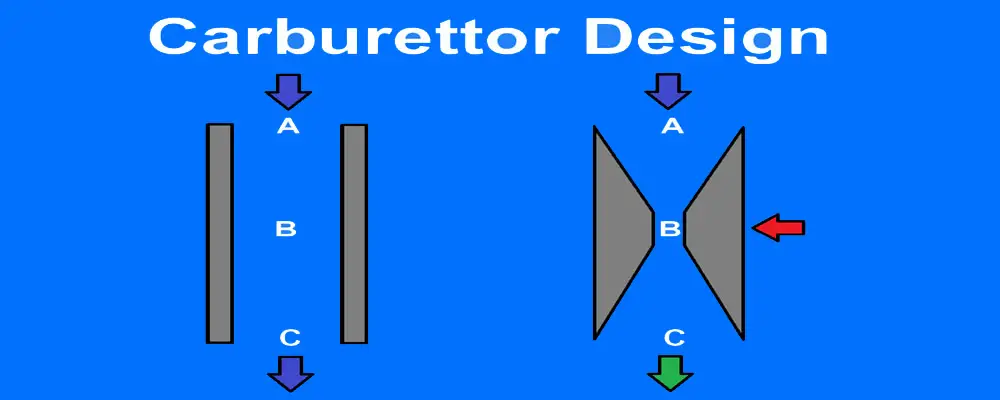

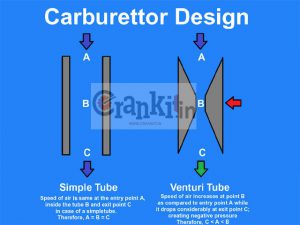

The Carburettor is nothing but a ’metal tubed structure’ known as ‘barrel’ or ‘venturi‘ that is narrower at the center. Thru’ this tube, the air passes to the engine cylinders. When the air enters the carburetor, its velocity/speed is constant. However when the air reaches the narrower end, its velocity starts to increase. This narrow end of the tube acts as a speed-booster for the incoming air. The speed of the air reaches the maximum level at the narrowest point of the barrel. This is due to the narrowing space thru’ which it must pass further. Once, the air passes the narrowest point, its velocity drops suddenly due to the immediate wider opening of the barrel.

This results in rapid drop in the pressure. Thus, it creates negative pressure. So, it allows the fuel pipe to lift the fuel from the carburettor’s float chamber and spray it into the incoming air. Here, the fuel mixes with the air proportionately. Then, the mixture passes on to the engine cylinders thru’ its intake manifold. Thus, the carburettor atomizes and vaporizes the fuel and mixes it with air according to engine’s changing operating conditions.

Carburettor: Design and Working Principle

In addition, a butterfly valve (throttle) is used to adjust the negative pressure. This enables mixing of fuel with air in varying proportions to suit engine’s operating conditions. The butterfly valve is attached to and controlled by the accelerator/throttle. It is further controlled by the driver of the vehicle or rider of the motorcycle as the case may be.

There are many more sub-systems which a carburettor uses to vary the air-fuel ratio. There are five main systems in the basic design which include – a Choke system, an Idling/Low-speed system, an Accelerating Pump system, a High Speed system and a Power system etc.

The Metering Systems:

Additionally, the Carb also uses compensating devices called “metering systems” to improve the performance. These include components such as metering rods, air-bleeding systems, economizers, compound jets and auxiliary air valves. These systems further correct the air-fuel ratio to make it as ideal as possible. More advanced designs deploy more than one barrel (double, triple & upto four barrels aka Quadra). These are known as Multiple-Barrel carburettors which deliver higher performance.

The multiple-barrel carburettors provide higher air flow rate for engines with large displacement. Multi-barrel designs can have non-identical, different-sized primary and secondary barrels; calibrated to deliver mixtures of different air-fuel ratios.

Advantages of a Carburettor:

- Simple design

- Economical to manufacture

- Easy to service

- Spares are affordable

- A local mechanic can fix it’s problems.

Disadvantages of Carburettor:

- Cannot provide a perfect air-fuel ratio consistently.

- Cannot control the wastage of fuel effectively.

- More number of parts in some complex designs which makes diagnosis difficult.

- Some designs develop the problem of vapour lock resulting in engine stalling.

- Delivers lower mileage & power as compared to fuel-injected systems.

Some of the popular manufacturers include Autolite, Bendix, Carter, Dell’Orto, Hitachi, Mikuni, Solex, Weber and Zenith etc. To overcome the deficiencies of the carburettor, the engineers later designed ‘Fuel-Injection’ systems.